Cosmetics Manufacturing Overview

The cosmetics industry is a rapidly growing and evolving industry. From color cosmetics to skincare to sun care, this industry aims to enhance customers’ sense of well-being. A vast majority of cosmetic products are chemical formulations that consumers apply either directly or indirectly to their skin. As such, the processes and equipment used in all stages of production must adhere to international and local hygiene standards to ensure the safety of the user. American Alloy has the equipment you need to stay at the forefront of cosmetic manufacturing and processing.

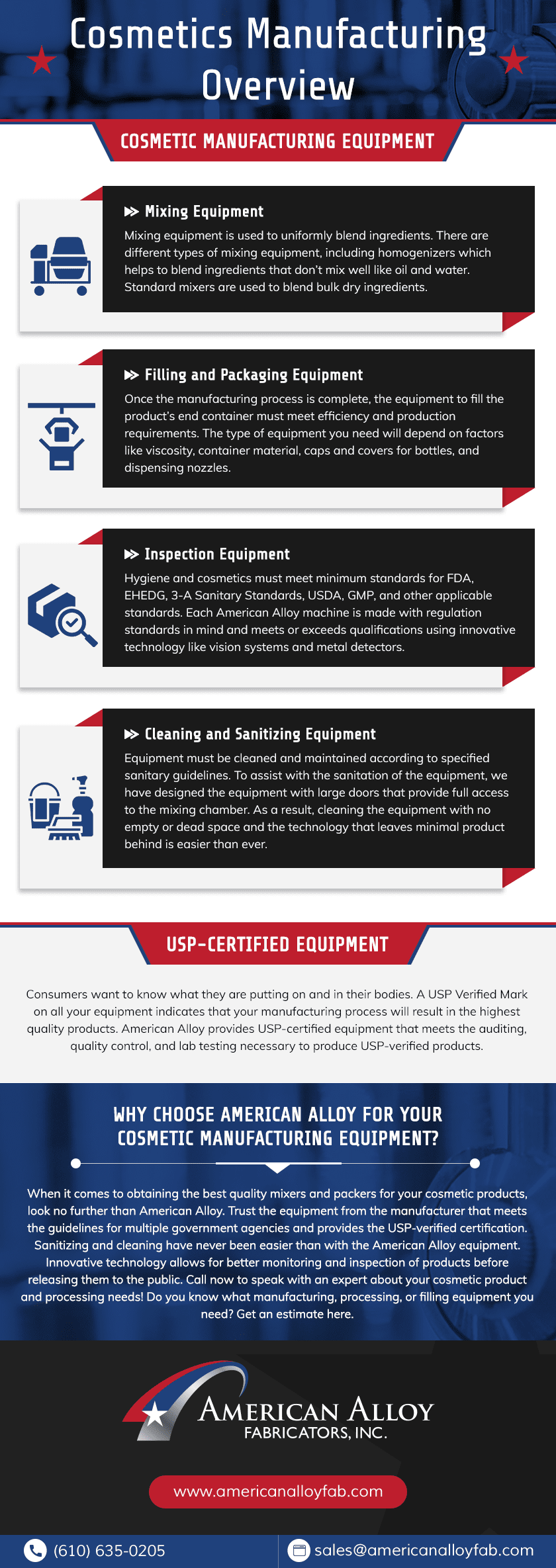

Cosmetic Manufacturing Equipment

Cosmetics and health products include powders, lotions, solid creams, spray-on-dry sprays, and more. Having the proper equipment in place will result in more efficient and cost-effective production processes. American Alloy offers the following equipment for the cosmetics industry:

- Mixing Equipment: Mixing equipment is used to uniformly blend ingredients. There are different types of mixing equipment, including homogenizers which helps to blend ingredients that don’t mix well like oil and water. Standard mixers are used to blend bulk dry ingredients.

- Filling and Packaging Equipment: Once the manufacturing process is complete, the equipment to fill the product’s end container must meet efficiency and production requirements. The type of equipment you need will depend on factors like viscosity, container material, caps and covers for bottles, and dispensing nozzles.

- Inspection Equipment: Hygiene and cosmetics must meet minimum standards for FDA, EHEDG, 3-A Sanitary Standards, USDA, GMP, and other applicable standards. Each American Alloy machine is made with regulation standards in mind and meets or exceeds qualifications using innovative technology like vision systems and metal detectors.

- Cleaning and Sanitizing Equipment: Equipment must be cleaned and maintained according to specified sanitary guidelines. To assist with the sanitation of the equipment, we have designed the equipment with large doors that provide full access to the mixing chamber. As a result, cleaning the equipment with no empty or dead space and the technology that leaves minimal product behind is easier than ever.

American Alloy provides the equipment necessary for easy mixing, curing, drying, and packaging. Each machine meets industry standards and is easy to clean and sanitize.

USP-Certified Equipment

Consumers want to know what they are putting on and in their bodies. A USP Verified Mark on all your equipment indicates that your manufacturing process will result in the highest quality products. American Alloy provides USP-certified equipment that meets the auditing, quality control, and lab testing necessary to produce USP-verified products.

Why Choose American Alloy for your Cosmetic Manufacturing Equipment?

When it comes to obtaining the best quality mixers and packers for your cosmetic products, look no further than American Alloy. Trust the equipment from the manufacturer that meets the guidelines for multiple government agencies and provides the USP-verified certification. Sanitizing and cleaning have never been easier than with the American Alloy equipment. Innovative technology allows for better monitoring and inspection of products before releasing them to the public. Call now to speak with an expert about your cosmetic product and processing needs! Do you know what manufacturing, processing, or filling equipment you need? Get an estimate here.