Process Piping

Process piping systems are used for the transmission of liquid and gas fluids for industrial applications, such as manufacturing, heat transfer, chemical processing, and more. Industrial facilities rely on process piping systems to provide heat, water, batch manufacturing processing, and more. This page will explore process piping, the key differences between process piping and plumbing, and how to ensure your facility has the best possible process piping.

Process piping systems are used for the transmission of liquid and gas fluids for industrial applications, such as manufacturing, heat transfer, chemical processing, and more. Industrial facilities rely on process piping systems to provide heat, water, batch manufacturing processing, and more. This page will explore process piping, the key differences between process piping and plumbing, and how to ensure your facility has the best possible process piping.

American Alloy Fabricators (AAF) manufacturers custom process piping to the most stringent customer specifications. We manufacture all process piping to ASME B31.3 standards and work with a variety of metals. Our extensive experience in the chemical, pharmaceutical, biotech, and food processing industries allows us to work with our clients to develop an ideal process piping solution to control the pressure, flow rate, and temperature of the transmitted fluids.

Download

DownloadWhat is Process Piping?

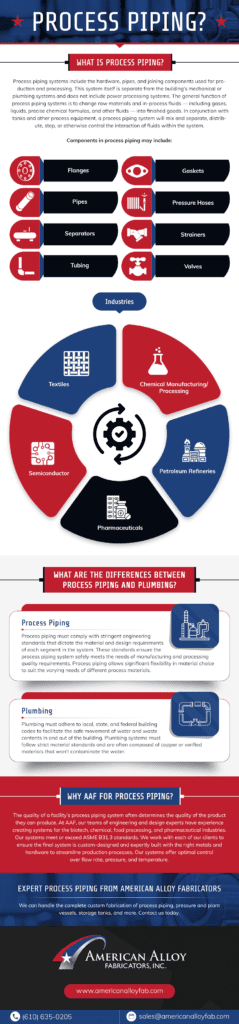

Process piping systems include the hardware, pipes, and joining components used for production and processing. This system itself is separate from the building’s mechanical or plumbing systems and does not include power processing systems. The general function of process piping systems is to change raw materials and in-process fluids — including gases, liquids, precise chemical formulas, and other fluids — into finished goods. In conjunction with tanks and other process equipment, a process piping system will mix and separate, distribute, stop, or otherwise control the interaction of fluids within the system.

Components in process piping may include:

- Flanges

- Gaskets

- Pipes

- Pressure Hoses

- Separators

- Strainers

- Tubing

- Valves

These components, among others, can be combined to create unique systems based on the specific needs of the product and layout of the facility. These industries rely heavily on process piping systems:

- Chemical manufacturing/processing

- Petroleum refineries

- Pharmaceuticals

- Semiconductor

- Textiles

What are the Differences Between Process Piping and Plumbing?

Process piping systems and plumbing systems look and operate very similarly. Both control the movement of fluids to perform certain tasks. However, they fulfill very different roles within an industrial building.

The purpose of a process piping system is to directly control fluids to produce a useable final product. This can include mixing systems, process piping systems for batch processing, and more. Plumbing systems specifically handle water supply and drainage for the facility itself, irrespective of the production taking place. The two systems may interconnect at certain points, such as when the process system disposes of wastewater via the plumbing system or the plumbing system provides water to the process system.

Due to their differing functions, process piping and plumbing follow different regulatory standards:

- Process piping must comply with stringent engineering standards that dictate the material and design requirements of each segment in the system. These standards ensure the process piping system safely meets the needs of manufacturing and processing quality requirements. Process piping allows significant flexibility in material choice to suit the varying needs of different process materials.

- Plumbing must adhere to local, state, and federal building codes to facilitate the safe movement of water and waste contents in and out of the building. Plumbing systems must follow strict material standards and are often composed of copper or verified materials that won’t contaminate the water.

Why AAF for Process Piping?

The quality of a facility’s process piping system often determines the quality of the product they can produce. At AAF, our teams of engineering and design experts have experience creating systems for the biotech, chemical, food processing, and pharmaceutical industries. Our systems meet or exceed ASME B31.3 standards. We work with each of our clients to ensure the final system is custom-designed and expertly built with the right metals and hardware to streamline production processes. Our systems offer optimal control over flow rate, pressure, and temperature.

Expert Process Piping from American Alloy Fabricators

At AAF, we specialize in custom process equipment builds. Our teams design and create process piping systems for a myriad of process materials found across a wide variety of industries. We can handle the complete custom fabrication of process piping, pressure and plant vessels, storage tanks, and more. Contact us today to see how we can help you improve your industrial process system.