Pilot Plant Vessels

At American Alloy Fabricators, we specialize in the design and manufacture of custom equipment for the biotechnology, chemical, food processing, and pharmaceutical industries. One of our core product offerings is pilot plant vessels.

At American Alloy Fabricators, we specialize in the design and manufacture of custom equipment for the biotechnology, chemical, food processing, and pharmaceutical industries. One of our core product offerings is pilot plant vessels.

What Are Pilot Plants?

Pilot plants are small-scale production systems utilized by manufacturers to test and verify the practicality of a new production technology or technique before proceeding to full-scale commercialization. While the primary objective of pilot plant projects is exploring and understanding the technology/technique, there can also be other secondary motivations depending on project organization and goals, such as:

- Scaling up production: gathering the necessary information to successfully establish a full-scale production facility

- Validating a technical process: testing the technology/technique to ensure it performs as expected

- Validating an economic process: providing proof-of-concept to investors and estimating the production costs and production yields of a full-scale plant

- Producing sample materials: creating product samples for internal evaluation/testing

- Developing the market: generating large-scale samples and small quantities for commercial distribution to build awareness and acceptance of the product

Each of these objectives can have a different effect on the design, cost, and timeline of the pilot plant project. As such, it is important to determine which ones are targeted early in the planning stage.

What Are Pilot Plant Vessels?

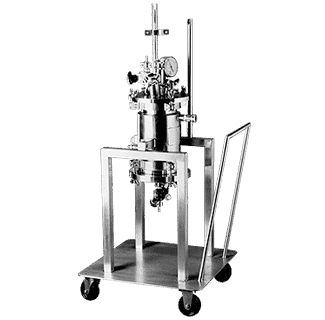

As suggested by the name, pilot plant vessels are vessels designed and built for use in pilot plants. Despite having smaller dimensions than the vessels used in full-scale plants, they accurately emulate full production conditions. The reduction in size allows manufacturers to set up a more cost-effective testing environment for process and production requirements.

The term “pilot plant vessels” encompasses a wide range of process equipment, such as heat exchangers and pressure vessels. These units are available with a variety of customization options to suit different processing applications, such as:

- Internal components: packed beds, trays, spray headers, liquid collection media, etc.

- Construction material: stainless steel and nickel alloys

- Configuration: standalone or modular skid assemblies

Benefits of Building a Pilot Plant

Pilots plants are often used to help manufacturers scale-up production. The data gathered while running the pilot plant provides them with a better understanding of what does and does not work.

Using computer-aided design and modeling software alongside pilot plants allows for an even greater understanding of the production technology/technique’s validity or invalidity as computational results can be compared to empirical observations. The findings from the comparison enable plant owners to make modifications to the computer model until it can accurately and reliably predict results for a wide range of operating parameters. This new and improved model can then be used as a tool to help develop larger or full-scale plants.

Cost of Building a Pilot Plant

There is no set matrix for the cost of a pilot plant. The price tag is highly situational. However, some factors can help gauge costs, such as:

- Complexity and scale of the process design. The greater the complexity and scale of a pilot plant, the greater the amount of equipment, design work, and development time needed. All of these elements require time and money.

- Operating conditions. Processing operations involving extreme pressures, temperatures, or flow rates require specialized equipment and systems, which generally means higher equipment costs.

- Construction and process materials. Highly specific or unique construction/process materials typically come at a higher price point than standard materials.

- Production level. Production output expectations affect the size and complexity of the system needed, both of which influence the overall cost. Larger production expectations require more extensive systems, meaning greater investment and production costs.

- Utility requirements. Pilot plant projects that require on-site modifications to meet the utility requirements of the processing operation will cost more than ones that already have the necessary equipment in place.

Why Partner With American Alloy Fabricators?

At American Alloy Fabricators, we design and manufacture custom, small-scale pilot plant vessels for basic and applied process research and laboratory applications. While we do not build pilot plants themselves, we work carefully to develop, engineer, and refine customer vessels to ensure they accurately emulate full-scale production conditions. As a result, our customers are better informed of the validity/invalidity of their new production technologies and techniques.

To learn more about our custom pilot plant vessel capabilities or discuss your requirements with one of our experts, contact us today.