Materials Used in Alloy Fabrication | American Alloy

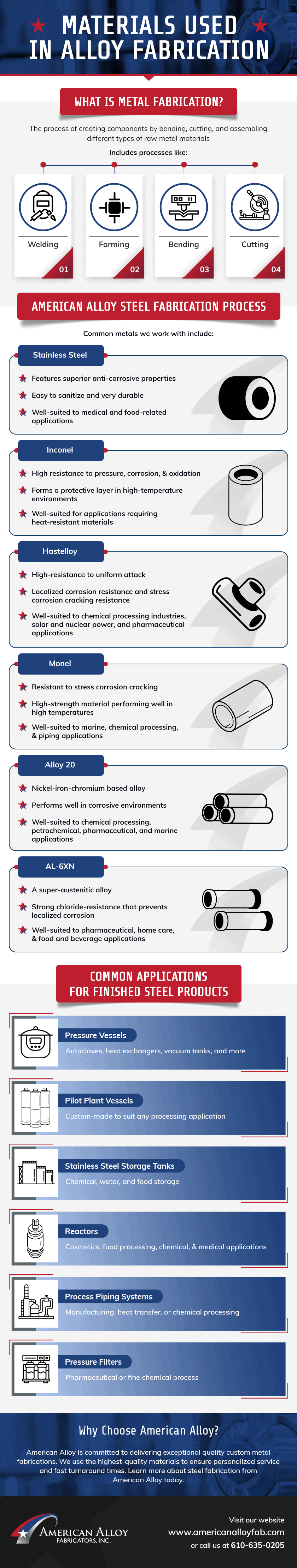

What is Metal Fabrication?

Metal fabrication is the process of creating components by bending, cutting, and assembling different types of raw metal materials. Automated technology as well as human labor are used to perform processes such as welding, riveting, hammering, and cutting using CNC cutters or handheld torches.

Metal fabricators can work with many substrates during fabrication processes, including steel, aluminum, brass, copper, and other metals. American Alloy prefers working with stainless steel due to its numerous beneficial qualities. Stainless steel is highly durable and long-lasting, as well as heat-resistant. It is able to retain its strength throughout even the most rigorous fabrication processes. Since it is easily recycled, it is also a highly sustainable choice.

American Alloy Steel Fabrication Process

As specialists in custom metal fabrication, American Alloy meets the needs of demanding industries using a catalog of high-performing materials. The most common metals we work with for steel fabrication include:

- Stainless steel: Features superior anti-corrosive properties and is easy to thoroughly sanitize, making it well suited to medical and food-related applications. Stainless steel is also very durable and can withstand weight and temperature extremes.

- Inconel: Highly resistant to pressure, corrosion, and oxidation, Inconel forms a protective oxide layer in high-temperature environments. This makes it well-suited for applications that require heat-resistant materials. Inconel is widely used in the aerospace industry in gas turbines, heat exchangers, heat shields, piping, valves, and more.

- Hastelloy: Features high resistance to uniform attack, excellent localized corrosion resistance, and stress corrosion cracking resistance, and is also easy to weld and fabricate. Hastelloy is widely used in the chemical processing industry, as well as in solar and nuclear power applications, pharmaceutical-related applications, and more.

- Monel: This high-strength material performs well in high-temperature applications and is also resistant to stress corrosion cracking. Its toughness makes it well-suited for marine, chemical processing, and piping applications.

- Alloy 20: A nickel-iron-chromium-based alloy that performs well in corrosive environments, including chemical environments that contain sulfuric acid or other aggressive media. It is widely used in chemical processing, petrochemical, pharmaceutical, and marine applications.

- AL-6XN: As a 6% molybdenum super-austenitic alloy, AL-6XN offers a strong chloride resistance, preventing localized corrosion. It is commonly used in pharmaceutical, home care, and food and beverage-related applications.

Common Applications for Finished Steel Products

Custom metal fabricators like American Alloy produce steel products that are used throughout nearly every industry. Our steel fabrication services most commonly meet the needs of the pharmaceutical, biotechnology, chemical, and food processing industries. Some of the many products that can be produced using alloy fabrication include:

- Pressure vessels: For autoclaves, heat exchangers, jacketed reactors, distillation towers, vacuum tanks, and more

- Pilot plant vessels: Customized to suit any processing application

- Stainless steel storage tanks: For chemical, water, or food storage

- Reactors: For use in cosmetics, food processing, chemical, and medical applications, among others

- Process piping systems: For manufacturing, heat transfer, or chemical processing applications

- Pressure filters: For pharmaceutical or fine chemical process applications

Why Choose American Alloy?

American Alloy is committed to delivering exceptional quality custom metal fabrications. We work with the most high-quality materials and always ensure personalized service with a quick turnaround time. To learn more about steel fabrication from American Alloy, reach out to our team today and start a conversation. Contact us to get started.