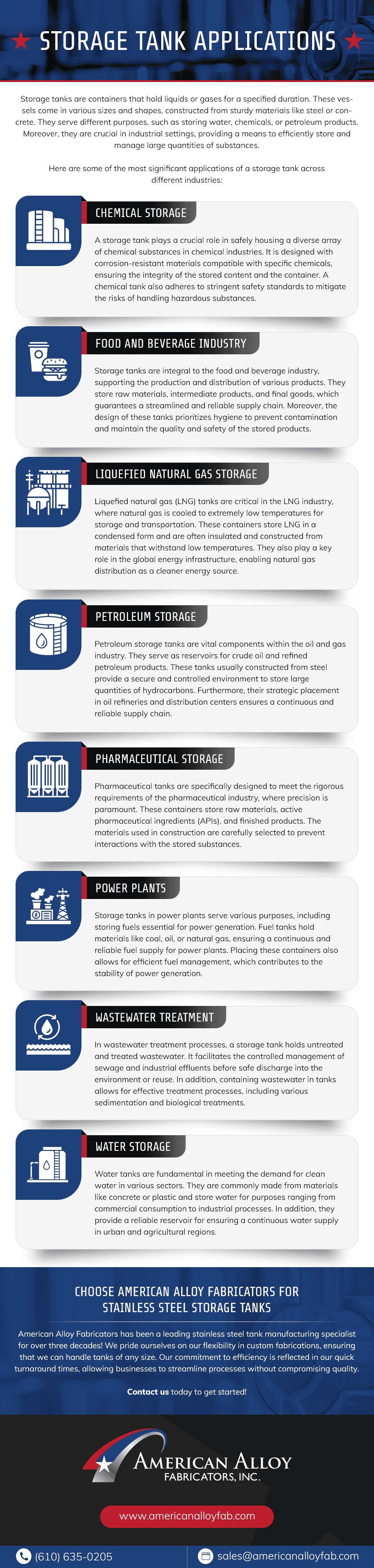

Storage tanks are containers that hold liquids or gases for a specified duration. These vessels come in various sizes and shapes, constructed from sturdy materials like steel or concrete. They serve different purposes, such as storing water, chemicals, or petroleum products. Moreover, they are crucial in industrial settings, providing a means to efficiently store and manage large quantities of substances.

Here are some of the most significant applications of a storage tank across different industries:

1. Chemical Storage

A storage tank plays a crucial role in safely housing a diverse array of chemical substances in chemical industries. It is designed with corrosion-resistant materials compatible with specific chemicals, ensuring the integrity of the stored content and the container. A chemical tank also adheres to stringent safety standards to mitigate the risks of handling hazardous substances.

2. Food and Beverage Industry

Storage tanks are integral to the food and beverage industry, supporting the production and distribution of various products. They store raw materials, intermediate products, and final goods, which guarantees a streamlined and reliable supply chain. Moreover, the design of these tanks prioritizes hygiene to prevent contamination and maintain the quality and safety of the stored products.

3. Liquefied Natural Gas Storage

Liquefied natural gas (LNG) tanks are critical in the LNG industry, where natural gas is cooled to extremely low temperatures for storage and transportation. These containers store LNG in a condensed form and are often insulated and constructed from materials that withstand low temperatures. They also play a key role in the global energy infrastructure, enabling natural gas distribution as a cleaner energy source.

4. Petroleum Storage

Petroleum storage tanks are vital components within the oil and gas industry. They serve as reservoirs for crude oil and refined petroleum products. These tanks usually constructed from steel provide a secure and controlled environment to store large quantities of hydrocarbons. Furthermore, their strategic placement in oil refineries and distribution centers ensures a continuous and reliable supply chain.

5. Pharmaceutical Storage

Pharmaceutical tanks are specifically designed to meet the rigorous requirements of the pharmaceutical industry, where precision is paramount. These containers store raw materials, active pharmaceutical ingredients (APIs), and finished products. The materials used in construction are carefully selected to prevent interactions with the stored substances.

6. Power Plants

Storage tanks in power plants serve various purposes, including storing fuels essential for power generation. Fuel tanks hold materials like coal, oil, or natural gas, ensuring a continuous and reliable fuel supply for power plants. Placing these containers also allows for efficient fuel management, which contributes to the stability of power generation.

7. Wastewater Treatment

In wastewater treatment processes, a storage tank holds untreated and treated wastewater. It facilitates the controlled management of sewage and industrial effluents before safe discharge into the environment or reuse. In addition, containing wastewater in tanks allows for effective treatment processes, including various sedimentation and biological treatments.

8. Water Storage

Water tanks are fundamental in meeting the demand for clean water in various sectors. They are commonly made from materials like concrete or plastic and store water for purposes ranging from commercial consumption to industrial processes. In addition, they provide a reliable reservoir for ensuring a continuous water supply in urban and agricultural regions.

Choose American Alloy Fabricators for Stainless Steel Storage Tanks

American Alloy Fabricators has been a leading stainless steel tank manufacturing specialist for over three decades! We pride ourselves on our flexibility in custom fabrications, ensuring that we can handle tanks of any size. Our commitment to efficiency is reflected in our quick turnaround times, allowing businesses to streamline processes without compromising quality.

Contact us today to get started!

Comments are closed