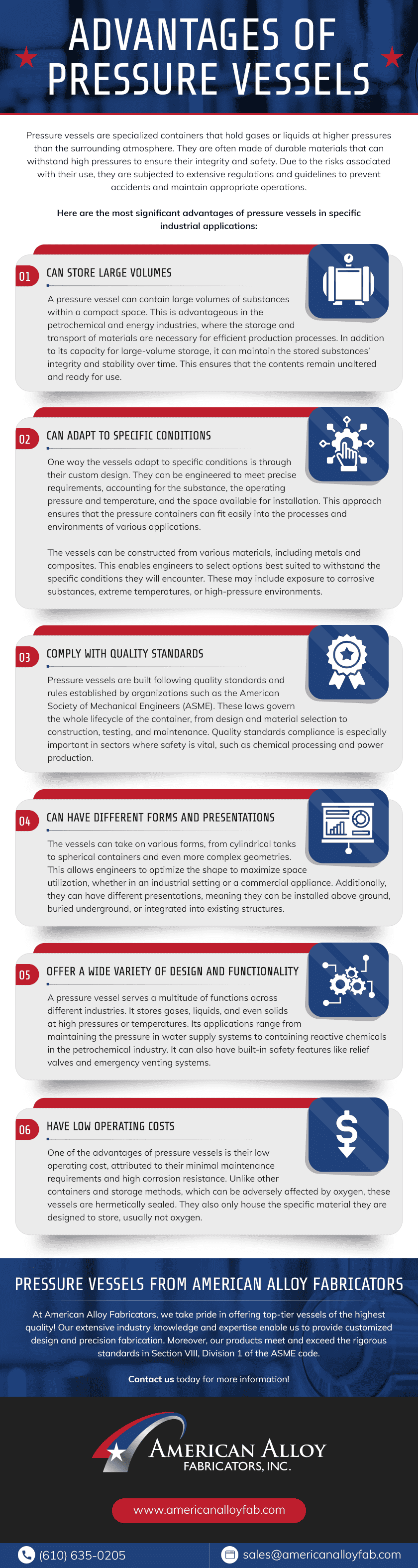

Pressure vessels are specialized containers that hold gases or liquids at higher pressures than the surrounding atmosphere. They are often made of durable materials that can withstand high pressures to ensure their integrity and safety. Due to the risks associated with their use, they are subjected to extensive regulations and guidelines to prevent accidents and maintain appropriate operations.

Here are the most significant advantages of pressure vessels in specific industrial applications:

1. Can Store Large Volumes

A pressure vessel can contain large volumes of substances within a compact space. This is advantageous in the petrochemical and energy industries, where the storage and transport of materials are necessary for efficient production processes. In addition to its capacity for large-volume storage, it can maintain the stored substances’ integrity and stability over time. This ensures that the contents remain unaltered and ready for use.

2. Can Adapt to Specific Conditions

One way the vessels adapt to specific conditions is through their custom design. They can be engineered to meet precise requirements, accounting for the substance, the operating pressure and temperature, and the space available for installation. This approach ensures that the pressure containers can fit easily into the processes and environments of various applications.

The vessels can be constructed from various materials, including metals and composites. This enables engineers to select options best suited to withstand the specific conditions they will encounter. These may include exposure to corrosive substances, extreme temperatures, or high-pressure environments.

3. Comply With Quality Standards

Pressure vessels are built following quality standards and rules established by organizations such as the American Society of Mechanical Engineers (ASME). These laws govern the whole lifecycle of the container, from design and material selection to construction, testing, and maintenance. Quality standards compliance is especially important in sectors where safety is vital, such as chemical processing and power production.

4. Can Have Different Forms and Presentations

The vessels can take on various forms, from cylindrical tanks to spherical containers and even more complex geometries. This allows engineers to optimize the shape to maximize space utilization, whether in an industrial setting or a commercial appliance. Additionally, they can have different presentations, meaning they can be installed above ground, buried underground, or integrated into existing structures.

5. Offer a Wide Variety of Design and Functionality

A pressure vessel serves a multitude of functions across different industries. It stores gases, liquids, and even solids at high pressures or temperatures. Its applications range from maintaining the pressure in water supply systems to containing reactive chemicals in the petrochemical industry. It can also have built-in safety features like relief valves and emergency venting systems.

6. Have Low Operating Costs

One of the advantages of pressure vessels is their low operating cost, attributed to their minimal maintenance requirements and high corrosion resistance. Unlike other containers and storage methods, which can be adversely affected by oxygen, these vessels are hermetically sealed. They also only house the specific material they are designed to store, usually not oxygen.

Pressure Vessels From American Alloy Fabricators

At American Alloy Fabricators, we take pride in offering top-tier vessels of the highest quality! Our extensive industry knowledge and expertise enable us to provide customized design and precision fabrication. Moreover, our products meet and exceed the rigorous standards in Section VIII, Division 1 of the ASME code.

Contact us today for more information!

Comments are closed