Inconel® represents a family of superalloys. Manufacturers prize these high-performance metal alloys for their impressive resistance to high temperatures, corrosion, oxidation, and creep. The passivation layer that forms on Inconel surfaces in the presence of heat and the fact that its grains do not grow in high-temperature environments give Inconel resistance strength even when facing extreme heat, high pressure loads, and corrosive chemicals.

Inconel® represents a family of superalloys. Manufacturers prize these high-performance metal alloys for their impressive resistance to high temperatures, corrosion, oxidation, and creep. The passivation layer that forms on Inconel surfaces in the presence of heat and the fact that its grains do not grow in high-temperature environments give Inconel resistance strength even when facing extreme heat, high pressure loads, and corrosive chemicals.

Sometimes considered Hastelloy, Inconel contains a variety of different materials in its composition, with nickel being the most prominent, followed by chromium. Depending on the included elements, varieties of Inconel will have unique characteristics and strengths. Two Inconel types with an array of beneficial properties for holding up in harsh environments are Inconel C276 and Inconel C22. Learn more about these alloys, what makes them advantageous, and about their applications.

Inconel C276 and C22

Of the Inconel alloys, C276 offers great versatility due to the wide array of situations and substances to which it is resistant. In addition to generally withstanding stress that would cause pitting or cracking in weaker alloys, even under extreme heat exposure, C276 holds up particularly well to acidic media, as well as alkalis, chlorides, solvents, and saltwater. The alloy has its composition of nickel, chromium, molybdenum, and a controlled Tungsten volume to thank for this.

Alternatively, Inconel C22—or Hastelloy C22—is another alloy of nickel, chromium, molybdenum, and tungsten with high corrosion resistance. In particular, it provides optimal aqueous corrosion and high-temperature resistance. This austenitic alloy can withstand stress and crevice corrosion as well, to limit the risk of cracking. The high percentage of chromium in C22’s content gives it a high resistance to oxidizing media, as well as sulfidation and carburization, and the nickel keeps the Inconel strong in the face of halides.

History of Inconel

Inconel is a registered trademark of Special Metals Corporation, which is based in New Hartford, New York. They are not, however, the original developers of Inconel materials. These alloys were initially designed to be used in high-temperature, high-stress environments in the 1900s. Inconel 600 was the first of its kind to hit the market, with applications in milk canisters in the 1930s. However, given its high nickel content, it can handle temperatures of up to 600° C for more modern applications in equipment such as nuclear reactors. Inconel 718 and Inconel 625 followed in the 1960s, and then Inconel 617. The latest alloy that Special Metals Corporation has trademarked is Inconel 693, which was developed in 2006 to resist metal dusting.

Inconel Applications for C276 and C22

With a virtually limitless amount of applications that rely on strong materials in high-temperature, high-pressure, and corrosive environments, Inconel C276 and C22 are versatile in that they find a place in so many industries. They are applicable in everything from the aerospace sector to pollution control.

Applications of Inconel C276

Capable of withstanding hydrochloric, sulfuric, and phosphoric acids, chlorine and wet chlorine gas, saltwater, and more, Inconel C276’s various applications include:

- Ducting, stack liners, and scrubbers for flue gas desulfurization (FGD) systems

- Heat exchangers, evaporators, reaction vessels, and piping within chemical processing operations

- Fans, fan enclosures, ducts, dampers, and stack-gas reheaters for pollution and wastewater management

- Surface and downhole parts for wells

Applications of Inconel C22

Inconel C22 is applicable in the production of highly varied materials, from cellophane to pesticides. Some applications include:

- Scrubbers and scrubber systems, such as SO2 scrubbers and incineration scrubber systems

- Chlorination and pickling systems

- Processing/reprocessing for wastewater and fuel

- Tasks at paper and pulp manufacturing plants

- Tubing and fittings in the pharmaceutical sector

American Alloy Fabricators: Your Partner for Your Inconel Needs

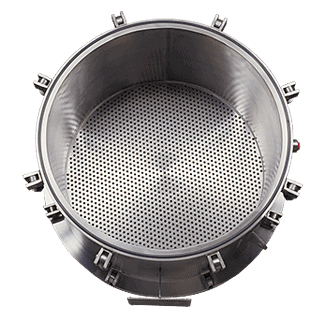

A number of specialty applications depend on Inconel for pressure filters and vessels as well as reactors, and the team at American Alloy Fabricators is here to help. Contact us to learn more about our commitment to quality and fast, personal service, or request an estimate today.

Comments are closed