ASME Section VIII is a key standard governing the design, fabrication, and inspection of pressure vessels. This section, part of the ASME Boiler and Pressure Vessel Code (BPVC), guarantees the safety, reliability, and regulatory compliance of pressure vessels used in a variety of industries. At American Alloy Fabricators, Inc., we specialize in custom pressure vessels that meet or exceed ASME code requirements, making high-quality products for critical applications.

What is ASME Boiler and Pressure Vessel Code?

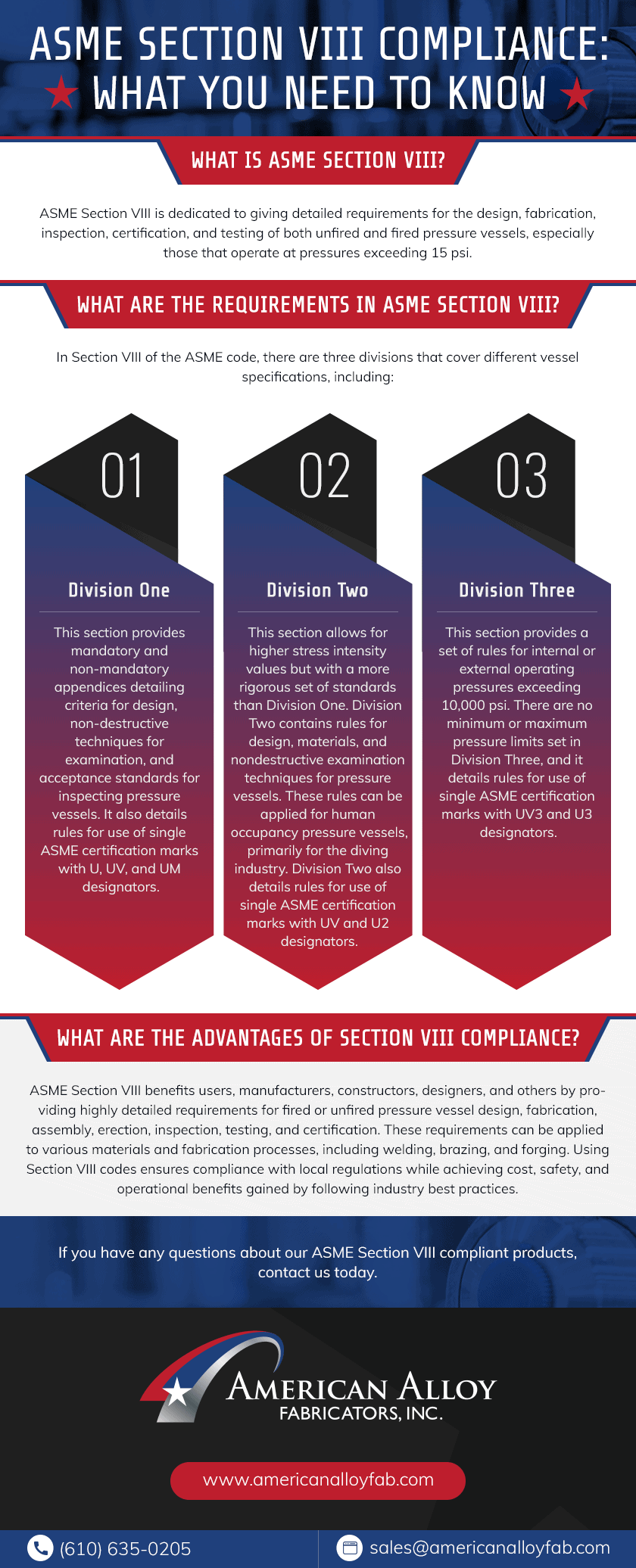

The ASME Boiler and Pressure Vessel Code (BPVC) is a collection of standards that regulate the design, manufacturing, and inspection of boilers and pressure vessels. Section VIII, which addresses pressure vessels, includes guidelines for materials, design calculations, welding procedures, and testing protocols. ASME code compliance is crucial for making sure that pressure vessels are safe, durable, and capable of withstanding high-pressure environments.

ASME Section VIII: Overview and Requirements

Section VIII of the ASME Code outlines the requirements for pressure vessels used in high-pressure or high-temperature applications. It is divided into three divisions:

- Division 1: General requirements for most pressure vessels.

- Division 2: Additional design requirements for vessels that operate at higher pressures.

- Division 3: Requirements for vessels designed for extremely high pressures.

Each division includes specific guidelines for design, material selection, fabrication, and testing to guarantee the pressure vessel meets safety standards and performs reliably.

Benefits of ASME Code Compliance for Pressure Vessels

ASME code compliance offers several key benefits:

- Safety: Pressure vessels that meet ASME standards are less likely to fail, reducing the risk of accidents.

- Reliability: Compliant vessels are more durable and dependable, ensuring continuous operation.

- Legal Compliance: Meeting ASME code requirements ensures compliance with industry regulations, preventing penalties and legal issues.

Inspection and Certification Process

Pressure vessels must undergo a detailed inspection process to achieve ASME Section VIII certification. This includes:

- Design Review and Approval: Review the pressure vessel design to ensure it aligns with ASME Section VIII requirements. Confirm design calculations, material selection, welding procedures, and safety features meet ASME Boiler and Pressure Vessel Code.

- Material Inspection: Verify that all materials meet ASME standards for quality and durability. Ensure materials are sourced from approved suppliers and their certifications match required specifications.

- Fabrication and Welding: Follow approved design and welding procedures during fabrication. Ensure welders are qualified, and welding procedures meet ASME standards.

- Non-Destructive Testing (NDT): Perform non-destructive testing (NDT) to detect structural issues, including ultrasonic testing (UT) for internal material flaws, radiographic testing (RT) for internal weld inspection, and magnetic particle testing (MT) and dye penetrant testing (PT) for surface defects.

- Hydrostatic Pressure Testing: Subject the vessel to a hydrostatic test by filling it with water and pressurizing it beyond its operational limits. Ensure the vessel holds pressure without leaks or deformation.

- Final Visual Inspection: Conduct a thorough visual inspection to ensure proper fabrication and assembly. Check for any overlooked defects or issues from earlier inspections.

- Certification and ASME U Stamp: Apply the ASME U Stamp to certify the vessel has been built, tested, and inspected according to ASME Section VIII standards. Ensure the vessel meets all safety, reliability, and regulatory compliance requirements.

- Third-Party Inspection: Work with certified third-party inspectors throughout the process to validate compliance with ASME standards. Inspectors review the design, materials, fabrication, and test results for full ASME Section VIII compliance.

Be Pressure Safe with American Alloy Fabricators, Inc.

Looking for custom pressure vessels that meet the highest safety and quality standards? Feel free to contact us to discuss your project needs and learn how our ASME Section VIII compliance guarantees reliable, safe solutions customized to your specifications. Reach out to our team today for expert guidance and a personalized quote!

Comments are closed