Industries Served

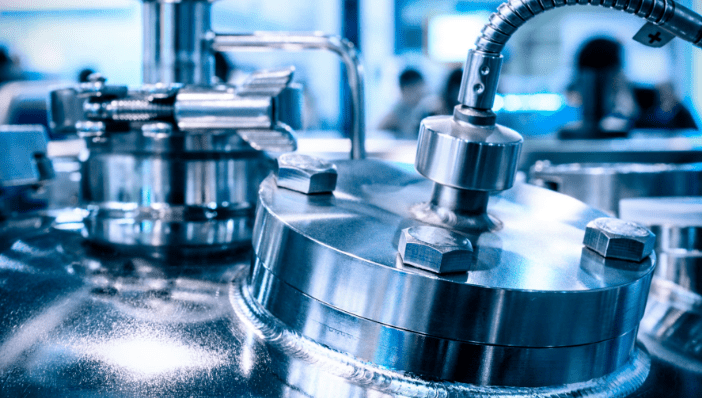

American Alloy Fabricators has been an industry leader for over three decades. We are a specialty metal fabrication company specializing in custom designs. Our ASME-certified equipment allows us to work with multiple industries. Upon our founding in 1989, we exclusively served clients in the pharmaceutical process industry, but have since expanded our capabilities, equipment, and facilities to serve a range of unique needs in many industries.

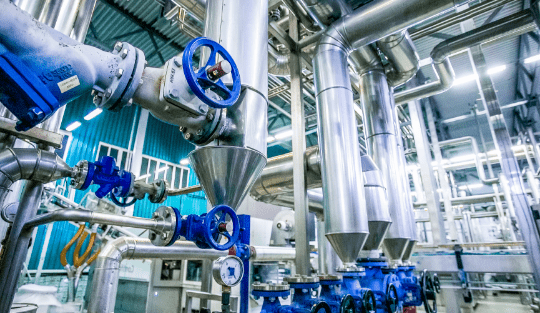

CHEMICAL

After becoming successful in the pharmaceutical sector, we expanded to serve the chemical industry. This began with the production of Hastelloy tanks. The initial project allowed us to develop a deeper understanding of the chemical industry. After accruing years of experience, we have earned a well-regarded reputation for fabricating high-end equipment for clients in the chemical field.

WITH OUR CAPABILITIES, OUR SHOP CAN MANUFACTURE THE FOLLOWING PRODUCTS FOR THE CHEMICAL MARKET:

- Pressure vessels

Pressure vessels

We manufacture pressure vessels, including reactors, columns, and storage tanks with varying diameters - Piping equipment

Piping equipment

We offer piping equipment in elbows and tee fittings with gaskets or flanges and individual straight lengths.

We also offer custom fabrication. Our team is available to manufacture plenums, dip tubes, injectors, thermal wells, and countless other pieces of equipment.

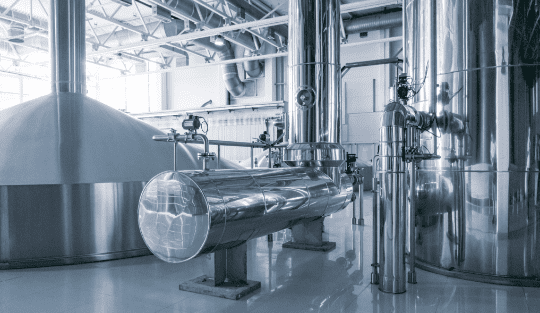

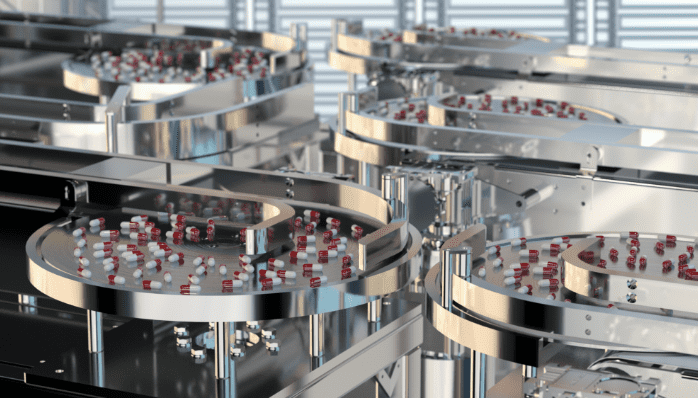

Pharmaceutical

Metal fabrication for the pharmaceutical industry is in our roots. When we first opened shop, our first clients were in pharmaceuticals. With over 30 years of serving pharmaceutical clients, we are well versed in the industry.

We understand that most pharmaceutical clients have higher sanitary requirements than other industries. Our shop is fully capable of manufacturing equipment derived from stainless steel which is compliant with cleanroom requirements. We hold the necessary certifications to manufacture other equipment pieces that meet the regulations of cleanroom environments.

American Alloy Fabricators can provide custom solutions when needed. Our most common equipment pieces include pressure vessels, storage tanks, process piping, and pressure filters, and our shop has the capabilities to make custom pieces with varying grades of stainless steel.

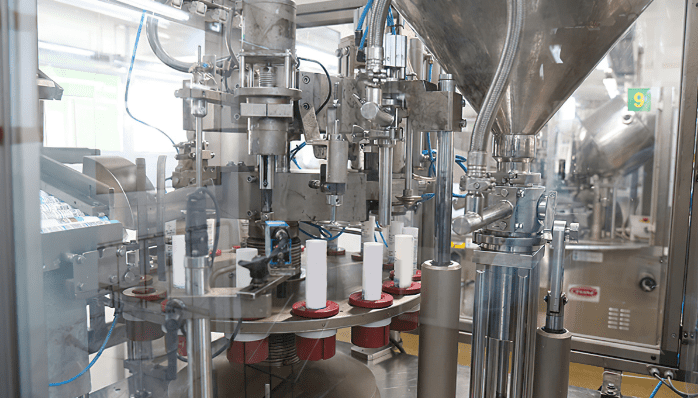

Cosmetics

Metal fabrication for the pharmaceutical industry is in our roots. When we first opened shop, our first clients were in pharmaceuticals. With over 30 years of serving pharmaceutical clients, we are well versed in the industry.

We understand that most pharmaceutical clients have higher sanitary requirements than other industries. Our shop is fully capable of manufacturing equipment derived from stainless steel which is compliant with cleanroom requirements. We hold the necessary certifications to manufacture other equipment pieces that meet the regulations of cleanroom environments.

American Alloy Fabricators can provide custom solutions when needed. Our most common equipment pieces include pressure vessels, storage tanks, process piping, and pressure filters, and our shop has the capabilities to make custom pieces with varying grades of stainless steel.

Our team is well versed in the needs of numerous industries. When it comes to storage tanks, pressure vessels, pilot plant vessels, process piping, pressure filters, reactors, or custom fabrications, we can craft a solution for virtually any industry. We have ASME-certified equipment, allowing us to work with even the most challenging industries. When needed, we can take a consultative approach with clients to develop the best solution.

If you have any questions about our capabilities, don’t hesitate to contact us anytime. If you already have a project in mind, feel free to REQUEST A QUOTE.