Stainless Steel Reactors

Reactor Pressure Vessels Built to Your Specifications

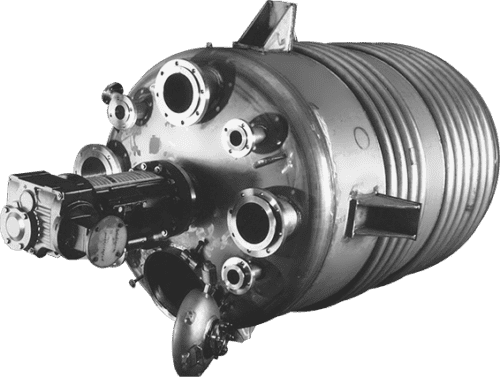

Reactors are vessels that are designed to contain chemical reactions related to distillation, extractions, and post-processing. Depending upon the intended application and industry, they can be constructed in various shapes, sizes, and forms, and can be made with numerous materials, including stainless steel and hastelloy. At American Alloy Fabricators, we design and fabricate reactors to our clients’ specifications while ensuring compliance with strict ASME requirements.

Industries that routinely use stainless steel reactors include, but aren’t limited to:

- Cosmetics

- Fermentation

- Food processing

- Medical

- Pharmaceutical

- Chemical

Jacketed Stainless Steel Reactors

When accurate temperature control is required, jacketed stainless steel reactors provide the optimal solution. The jackets create a pocket around the reactor that allows fluid to circulate to either heat or cool the container. This design ensures uniform heat exchange between the circulating fluid, the walls of the vessel, and the processed contents.

Different types of jacketed reactors include:

Conventional Jacketed Stainless Steel Reactors

Conventional or open jacket reactors have an external shell that surrounds the primary vessel to provide a space for heat transfer fluid. This style of stainless steel reactor offers the most coverage; however, it is often the thickest and heaviest jacket option, as the pressure of the jacket is applied as external pressure to the inner vessel. American Alloy Fabricators manufactures our conventional jacketed pressure reactor with a spiral-formed internal baffle that guides the heating fluid around the tank.

Half-Pipe Jacket Stainless Steel Reactors

A half-pipe jacketed reactor has piping that is welded to the outside of the tank. They allow high flow rates and employ hot oil and other media, making them ideal for high pressure and temperature applications. To increase fluid velocity and minimize pressure, we use a 180° design. The continuous coil formation of our half-pipe reactor can be wrapped in one or more zones.

Dimple Jacketed Stainless Steel Reactors

The dimple jacketed reactor provides excellent heat transfer, along with low pressure, temperature, and flow rates. The surface is embedded with a series of equally spaced dimples that make the tank lightweight and cost-effective. While not appropriate for thermal shock or extreme temperature changes, this type of stainless steel reactor pressure vessel is a good choice for steam heating or water cooling. American Alloy Fabricators ensure a secure fit by rolling our dimpled jacket around the tank then plug welding the dimples to the vessel.

The dimple jacketed reactor provides excellent heat transfer, along with low pressure, temperature, and flow rates. The surface is embedded with a series of equally spaced dimples that make the tank lightweight and cost-effective. While not appropriate for thermal shock or extreme temperature changes, this type of stainless steel reactor pressure vessel is a good choice for steam heating or water cooling. American Alloy Fabricators ensure a secure fit by rolling our dimpled jacket around the tank then plug welding the dimples to the vessel.

Why Work With American Alloy Fabricators?

American Alloy Fabricators, Inc. has been a highly effective and reliable reactor manufacturer for over 30 years. Our stainless steel reactor pressure vessels are built to your exact specifications using a wide range of materials, including various grades of stainless steel reactors and stainless steel, Monel, Inconel, Hastelloy, and other alloys.

At American Alloy Fabricators, we offer:

- ASME code reactors that are licensed up to 3000 psi.

- Your choice of half-pipe, dimpled, and conventional jacketed reactors.

- A selection of agitated, mechanical, and magnetic designs.

Our stainless steel reactors are designed, fabricated, inspected, and stamped per Section VII, Division 1 of the ASME code. We offer various levels of mechanical and electropolishing on the interior of the reactor, with up to an 8 Ra mechanical polish or a 4 Ra electropolish interior finish. Our history of long-term relationships with some of the largest companies in the world speaks to our commitment to providing the highest quality products and services.

Custom Reactor Pressure Vessels

Pressure vessels that contain liquid or gaseous substances under internal or external pressure must be fabricated to exacting specifications and in strict conformance with ASME regulations. American Alloy Fabricators builds reactors and other equipment for biotechnology, chemical, pharmaceutical, and food processing industries for multiple applications. Our team of custom stainless steel solution experts has years of training, experience, and certifications to ensure the highest level of safety and quality.

If your business requires managing and controlling process temperatures or pressure, talk to our team of experts about your needs. We will work with you to create a custom reactor based on the requirements and specifications of your application. Contact us today to get started on your custom reactor pressure vessel.