Process Piping in the Pharmaceutical Industry

Comments Off on Process Piping in the Pharmaceutical IndustryThe pharmaceutical industry requires high-quality process piping systems to ensure the safe and efficient transportation of fluids and gases within manufacturing facilities. These systems must adhere to rigorous regulatory standards to guarantee the products’ integrity and purity. They must also be corrosion-resistant and capable of withstanding the meticulous cleaning and sterilization procedures.

In this article, we will examine the critical role of industrial piping systems in the efficiency and effectiveness of pharmaceutical operations.

Roles of Process Piping Networks in the Pharmaceutical Sector

The following roles of piping networks ensure the continuous and reliable production of high-quality pharmaceutical products:

Material Transport

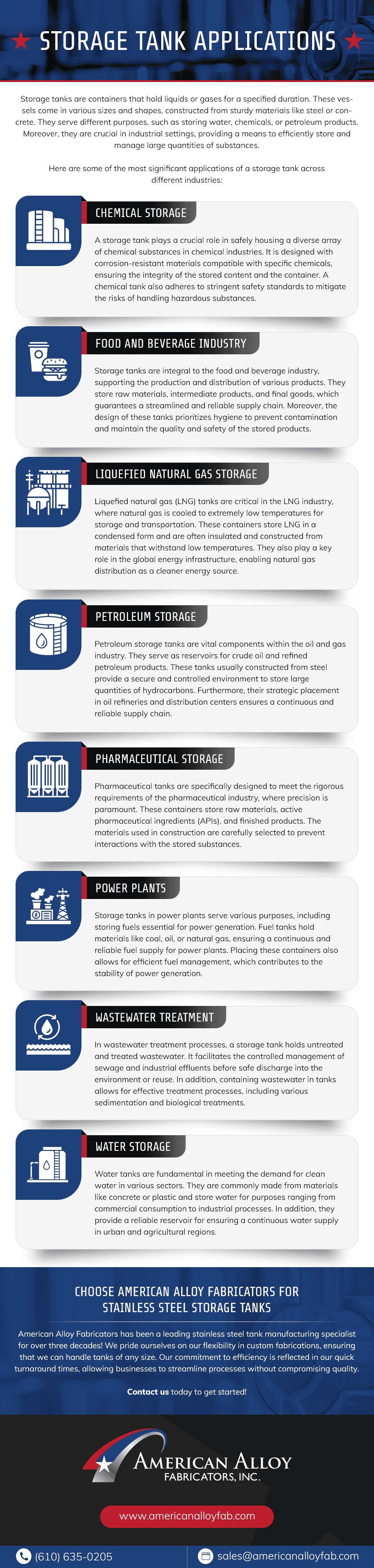

Piping networks form the arterial system of pharmaceutical manufacturing plants, facilitating the flow of raw materials, intermediates, and final products. Without efficient systems, manufacturing operations would have delays and bottlenecks. They connect various processing units such as reactors, mixers, centrifuges, and storage tanks ensuring seamless substance movements.

Process Integration

Efficient piping networks enable the continuous and coordinated movement of materials by linking various unit operations, such as synthesis, purification, filtration, and formulation. This integration streamlines production workflows, minimizes idle time between operations, and enhances overall manufacturing efficiency. Moreover, it allows for real-time adjustments and process optimization.

Product Quality Assurance

Piping networks play a crucial role in ensuring the quality and consistency of pharmaceutical products. By maintaining precise control of flow rates, pressure, and temperature, these networks contribute to the reproducibility and uniformity of manufacturing processes. Quality assurance measures integrated into piping systems also help minimize variations in product characteristics.

Safety and Environmental Protection

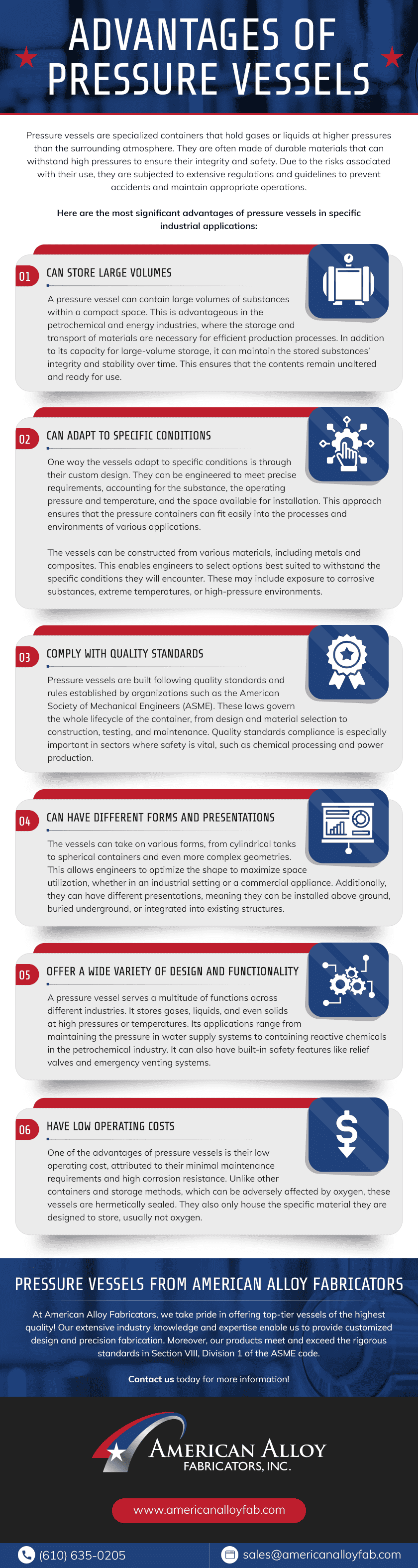

Process piping systems are engineered with safety and environmental considerations to prevent accidents, protect personnel, and minimize environmental impact. Measures such as pressure relief valves, rupture discs, and containment systems are incorporated to mitigate the risk of overpressure events. Secondary containment and leak detection systems are also implemented to prevent environmental pollution.

Sterility Maintenance

Pipes made from specialized materials like stainless steel, glass, and high-grade polymers are employed to prevent contamination and maintain product purity. They also often have sanitary fittings, smooth internal surfaces, and sterilize-in-place (SIP) capabilities to guarantee thorough cleaning and sterilization. These measures safeguard against microbial contamination, endotoxin buildup, and particulate contamination.

Utility Distribution

Piping networks are conduits for distributing essential utilities required for pharmaceutical manufacturing processes. These utilities include purified water, steam, compressed air, nitrogen, and process gases conveyed through the networks to support various production activities. For instance, purified water is used for formulation, cleaning, and equipment rinsing, while steam is utilized for sterilization.

American Alloy Fabricators’ Approach to Process Piping Systems

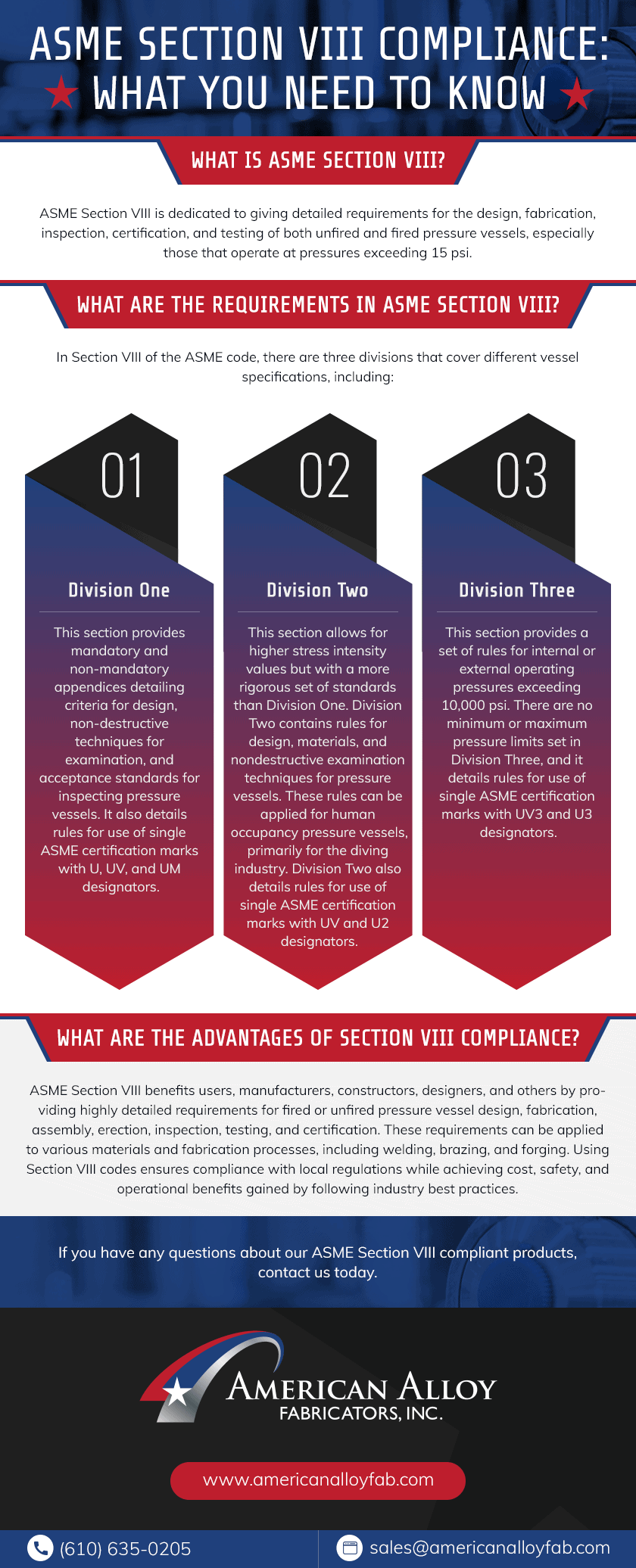

American Alloy Fabricators (AAF) meticulously designs and manufactures piping systems to cater to the needs of the pharmaceutical industry. Our team strictly adheres to ASME B31.3 standards, which ensures the highest level of quality and compliance with industry regulations. We also collaborate closely with clients to develop custom piping solutions tailored to their requirements.

AAF’s commitment to excellence extends beyond the initial design and manufacturing phases to ongoing client collaboration. By actively engaging with clients, we ensure that the final piping system meets their unique needs and expectations. In addition, our systems are specially designed to enhance productivity, minimize downtime, and maintain product integrity.

Choose American Alloy Fabricators for Your Piping Needs

At AAF, we take pride in our expertise in process equipment builds! We design and create industrial piping systems tailored to the unique needs of industries ranging from pharmaceuticals to food processing. We also excel in fabricating pressure and plant vessels, storage tanks, and other components for efficient industrial operations.

Contact us today to get started.

At American Alloy Fabricators, we provide the highest quality pressure vessel products. Our expert team offers

At American Alloy Fabricators, we provide the highest quality pressure vessel products. Our expert team offers